Technology that makes the difference

For deep drilling shafts that shine in action

.

.

With single-lip deep drilling shafts, every detail determines precision, stability and process reliability. That’s why we combine high-quality base material with state-of-the-art manufacturing technology – for deep drilling shafts that impress in use.

High-quality base material

Our production starts with selected, high-quality base materials. Only an optimally suitable shaft blank enables the process stability that a single-lip drill requires later on. Material quality is non-negotiable – it is the basis of every successful drilling process.

High-quality base material

Our production starts with selected, high-quality base materials. Only an optimally suitable shaft blank enables the process stability that a single-lip drill requires later on. Material quality is non-negotiable – it is the basis of every successful drilling process.

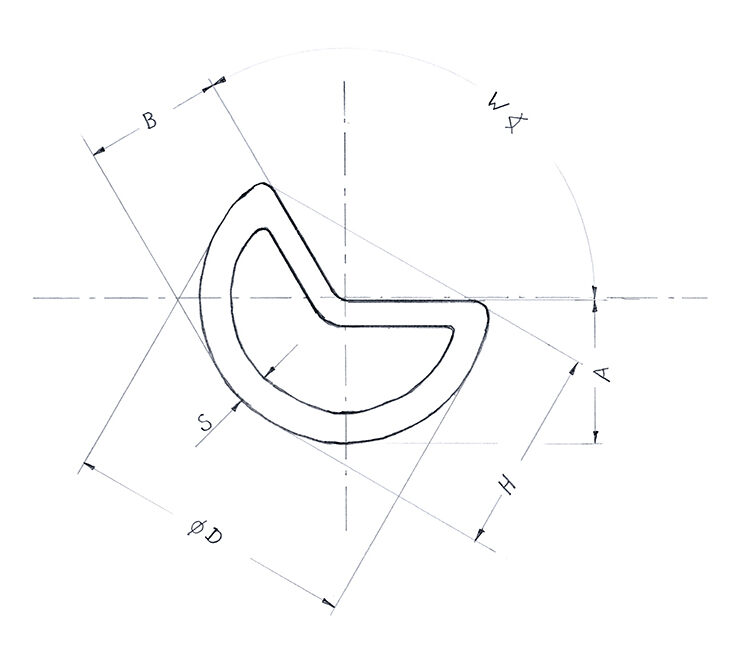

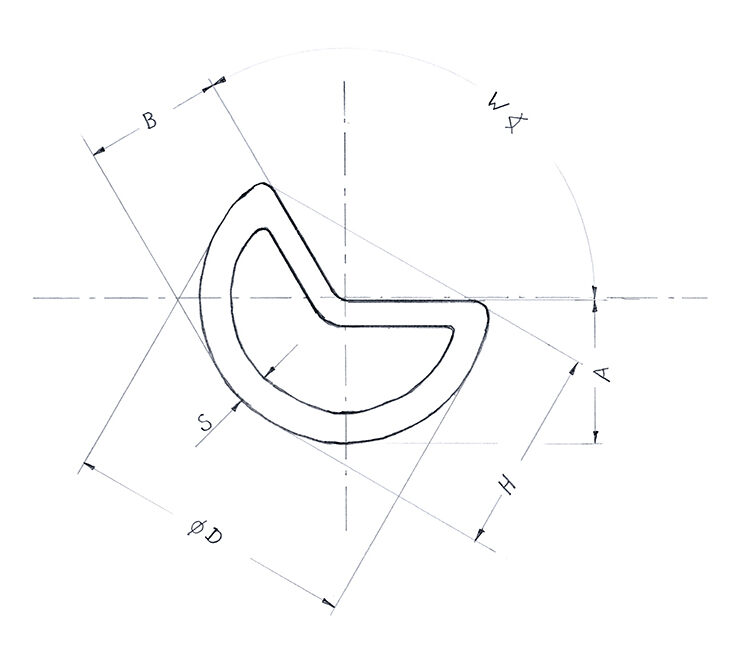

Optimized geometries and materials

Through continuous development and numerous detailed optimizations, we improve the geometries and material properties of our deep drilling shafts. Each adjustment pursues one goal: maximum stability, buckling resistance and service life in the real drilling process.

- Innovative materials

- Optimized wall thicknesses

- Precise internal geometries for optimum flow

.

.

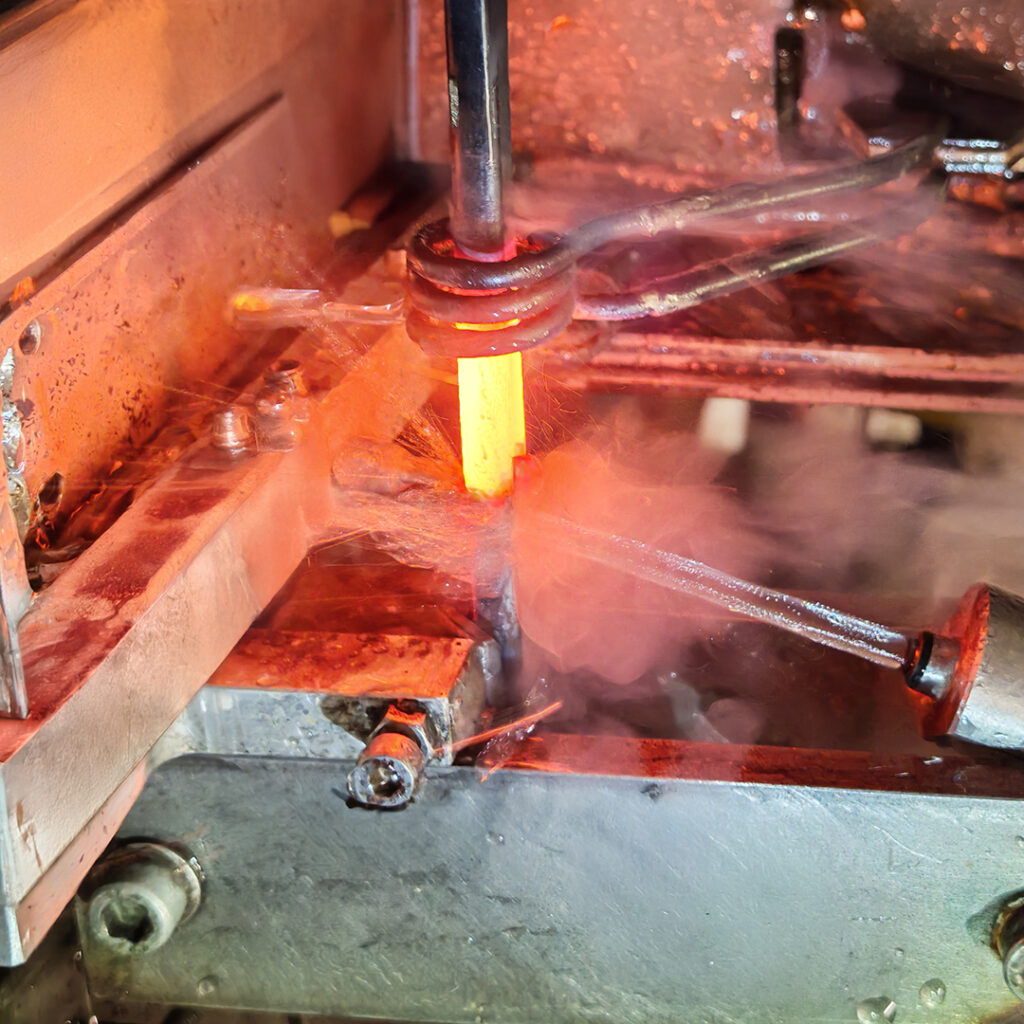

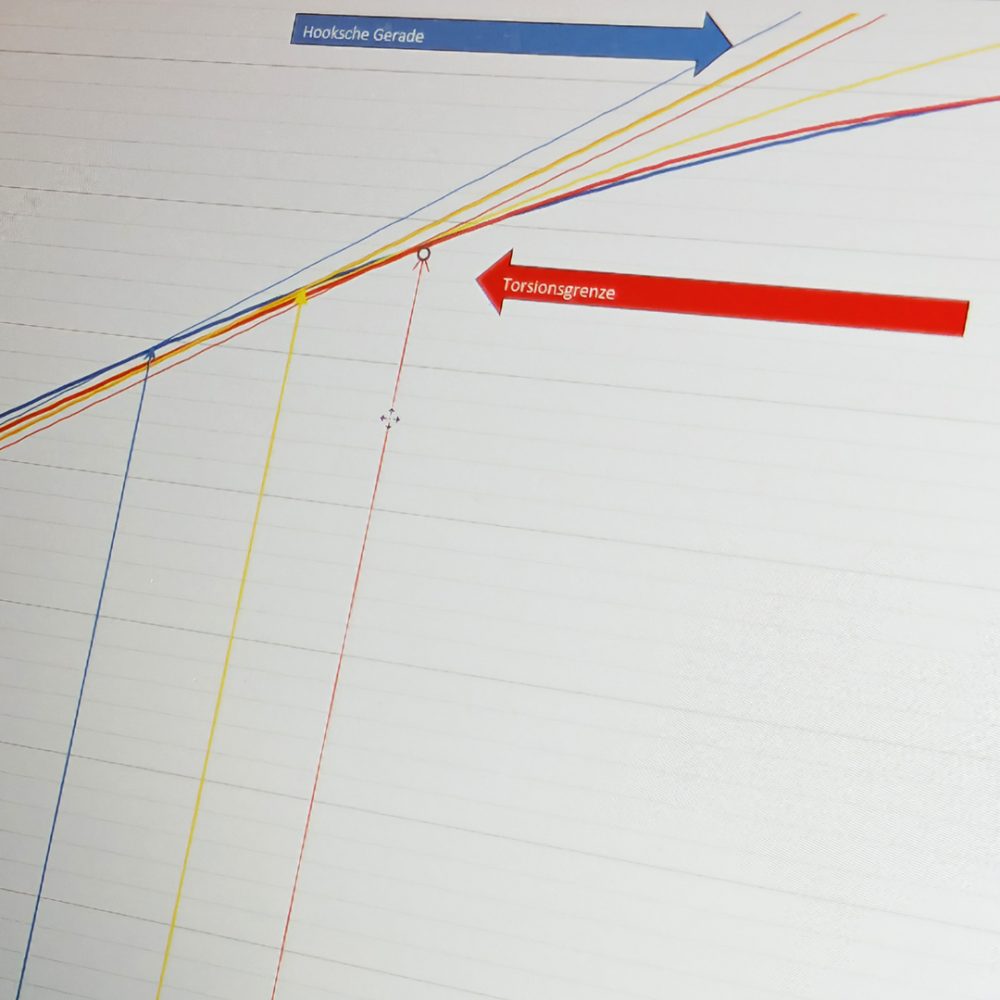

Controlled heat process

Heat treatment is crucial for hardness and elasticity. It determines the load capacity up to the torsional limit of the deep drilling shaft. We use computer-aided temperature profiles that are exactly repeatable. This is how we guarantee constant quality values – from batch to batch.

Controlled heat process

Heat treatment is crucial for hardness and elasticity. It determines the load capacity up to the torsional limit of the deep drilling shaft. We use computer-aided temperature profiles that are exactly repeatable. This is how we guarantee constant quality values – from batch to batch.

Optimum torque and buckling resistance

With state-of-the-art manufacturing equipment, we ensure that torque resistance and buckling stability exactly meet the requirements. Precise straightening processes and high-resolution measuring systems guarantee absolute straightness and homogeneity over the entire length.

- High-resolution torque testing

- Automated logging of all values

.

Process reliability – why precision is crucial

With single-lip drills, all parameters, influences and dimensional accuracy must be exactly right – including those of the deep drilling shaft. Even small deviations can lead to unstable drilling behavior or tool failure.

That is why we rely on consistently repeatable manufacturing processes and complete traceability of all production steps. This is the only way a single-lip drill can work permanently with process reliability.

Leaving nothing to chance

We are convinced that process reliability is created by control results that flow back into the manufacturing process. That is why we monitor every manufacturing step – from raw material to final inspection – and leave no parameters to chance.

Adaptation to your drilling process

Thanks to our many years of experience, we can adapt deep drilling shafts specifically to your machines, requirements and process conditions. Please do not hesitate to contact us – we will take the time for your application.

.

Deep drilling shafts – reliable, precise, Made in Germany.