The roots of single-flute drilling lie in the early methods of gun drilling. As early as the 18th and 19th centuries, there was a need to produce long and straight bores for rifle and cannon barrels.

Single-edged cutting tools that guided themselves were used at that time – a principle that was later further developed into the single-flute drill. These early methods were slow, but for the first time enabled exceptionally straight bores. For the time, this was a technological breakthrough.

The actual progress of single-flute drilling took place after the Second World War. Several developments came together:

- High-pressure cooling lubricants became available

- Carbide could be used industrially and reliably

- Industry demanded increasingly precise deep hole drilling

During this phase, the modern single-flute deep hole drill with carbide head was developed, as it is still used today.

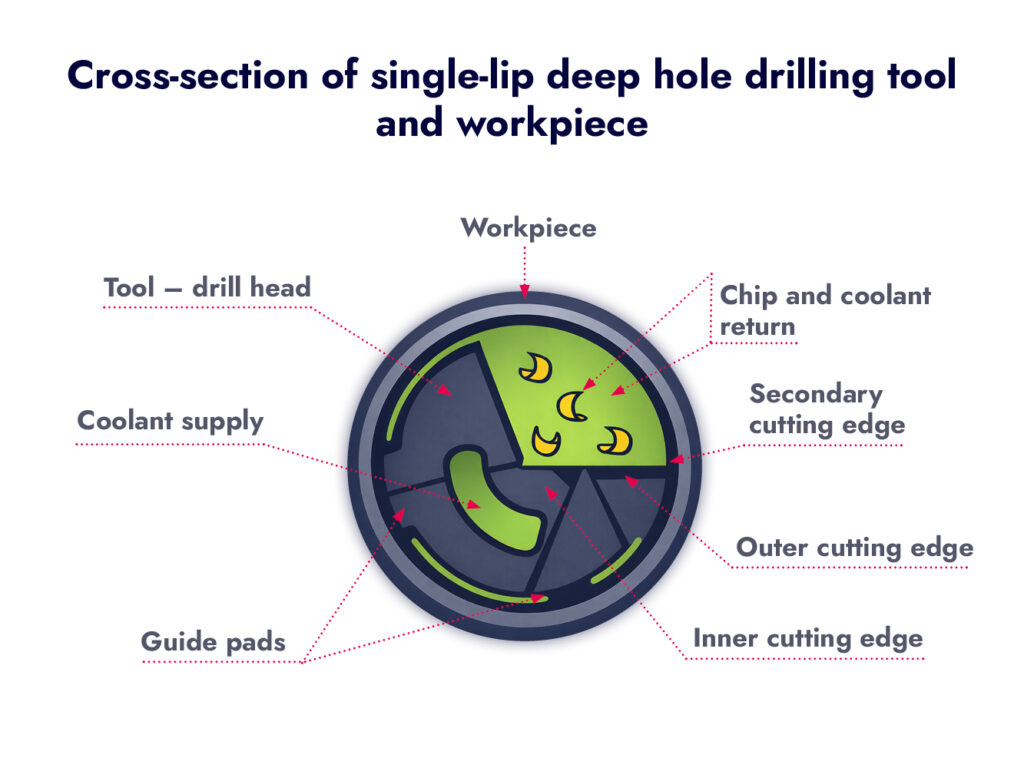

A single-flute deep hole drill (SFD) is a single-edged, self-guiding deep hole drilling tool that has been developed for the precise drilling of very deep, straight and dimensionally accurate bores. It has an inner and an outer cutting edge, guide rails for stabilisation in the borehole and an internal coolant supply.

The high-pressure cooling lubricant reaches the cutting edge directly via this supply. The resulting chips are then discharged from the borehole together with the cooling lubricant via the V-shaped chip flute.

For spot drilling, a single-flute drill requires a defined guide, for example in the form of a drill bush or a pilot hole.